3d Printer Clogging (Swollen Filament)

I have been having misprints with my Creality Ender 3 3d Printer. Specifically nozzle clogging. The following is my journey into the rabbit hole of my Ender 3 and the filaments I used.

At first I reviewed the forums looking for some insight, I assumed that the problem stemmed from me buying cheaper PLA Filament. The forums said that cheap filaments have some impurities and higher water content and might contribute to the clogging issue. I changed the filament to a new roll of eSun Black PLA, a more premium grade (in my humble opinion). The problem continued.

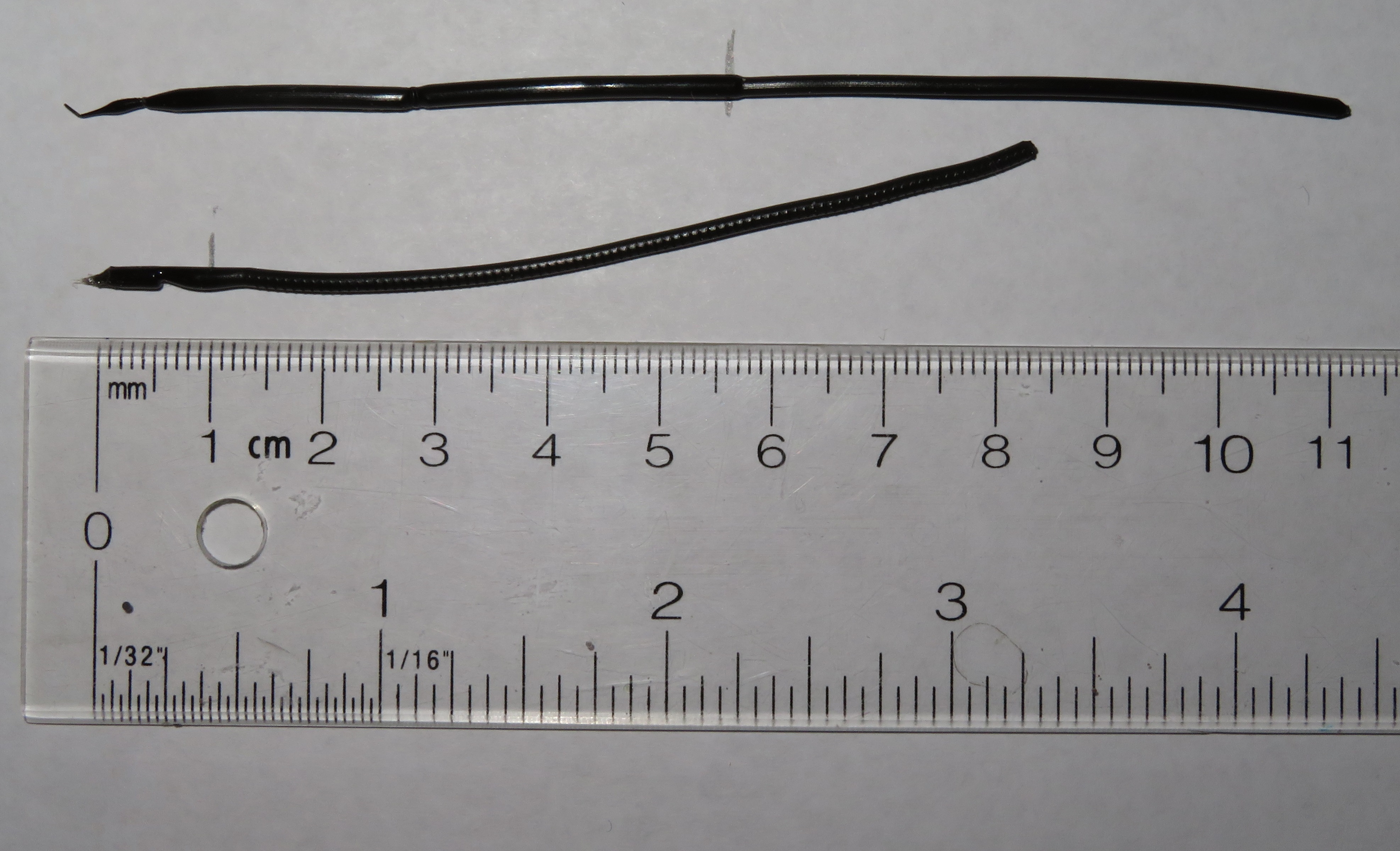

While unclogging the nozzle I pulled the filament from the extruder head and noticed that the filament had swollen to 2mm in diameter for about 55mm in length (see image below). I checked the the fan and it ran fine. The forums suggested that I checked the Bowden tube and noticed an excessive amount of sticky-ness, which was a sign of the tube being over-exposed to heat. I had replaced my tube only a few weeks earlier. I had bought the tube on-line at Amazon and had bought some Capricorn tubing (the forums suggested that some crooked suppliers did not provide actual Capricorn tubing, but some in-expensive after market product). I replaced the tubing. The problem continued.

People suggested that the temperature was too high in the nozzle. I borrowed a IR Thermometer and it showed that the set temperature was correct to within a 1-2 degrees. The problem continued.

People on forums suggested that I lower the Retraction Amount to less than 5mm. The problem continued.

Finally, I was trying some obscure settings in Cura, and decided to sit and watch it print for a few minutes. Then I saw the issue... It seems that the Hot End fan had an issue. It was the original fan and had been running for over a year now, the bearing must have heated up and wore the housing out so that the fan bearing could move in the housing. Once a printed started the bearing was cool and ran fine, as it heated up the bearing would allow the fan blades to move and jam against the housing. This occurred about 15-20 minutes into the print. The fan would stop cooling the hot end heat sink and allow the heat to transfer up the heat sink and over heat the filament and Bowden tubing. At the end of the job the head would cool down and the fan would pop back into position and start running.

Damn...